Okay, so let me tell you about this one time with a magnetic drive pump. I was setting up this little system in my garage, trying to circulate some coolant for a project I was tinkering with. Wasn’t anything too complicated, just needed to move some liquid from point A to point B.

I got the pump all plumbed in, connected the hoses, and I thought I had everything primed properly. You know, filled the lines, made sure there was liquid up to the pump inlet. I flicked the power switch on. Heard that familiar quiet hum these magnetic pumps make. Everything seemed smooth, seemed like it was working just fine. Water was flowing, looked good.

Then, like an idiot, I got sidetracked. I think my phone rang, or maybe I went to grab a different tool, I don’t remember exactly. Point is, I walked away for maybe five, ten minutes, leaving the pump running. Wasn’t really thinking about it, just figured it was doing its job.

When I came back, I heard this noise. It wasn’t the smooth hum anymore. It was this louder, kind of strained, almost grinding sound. Not super loud, but definitely not right. My stomach kind of dropped. I immediately looked at the reservoir tank I was pumping from.

It was empty. Completely dry. The pump had sucked all the liquid out and was just spinning in air. That awful noise was the impeller spinning with no liquid to cool or lubricate it.

Man, I lunged for the power switch and shut it off immediately. You could feel the pump casing was pretty warm, warmer than it should be just from running normally. Didn’t smell any smoke, thankfully, but it was definitely hot from friction.

Checking the Damage

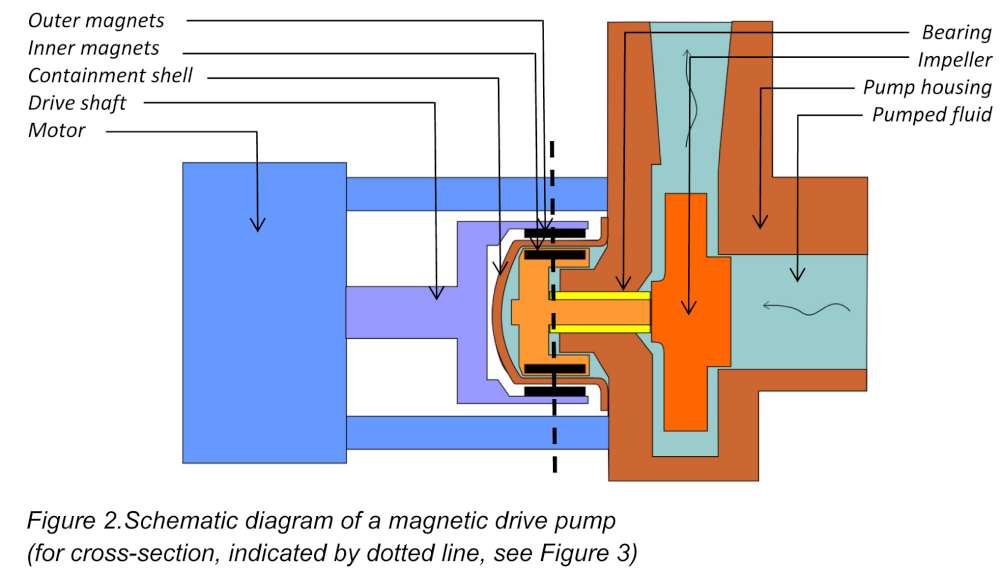

I let it sit there for a good half hour to cool down completely. Honestly, I was expecting the worst. Figured I’d melted the impeller or warped the housing. These magnetic drive pumps are great because they don’t have seals that can leak, but running them dry is supposed to be a big no-no.

After it cooled, I did a few things:

- I disconnected the outlet hose to relieve any pressure.

- I refilled the reservoir tank, making absolutely sure this time.

- I carefully primed the pump again, bleeding air out of the lines.

Then came the moment of truth. I took a breath and flipped the switch back on. It started up. The noise… well, it sounded okay. Maybe a tiny bit rougher than when it was brand new, or maybe I was just listening extra hard, feeling guilty. But it was pumping liquid again, flow looked normal. No horrible grinding sounds this time.

I guess I got incredibly lucky. Maybe shutting it off quickly saved it. I’ve heard stories of these things seizing up or melting down completely when run dry for too long. The heat buildup from the impeller spinning against the housing without any liquid is the real killer.

So, the lesson learned? Keep an eye on your fluid levels! Especially during startup or if it’s a new setup. Don’t just turn it on and walk away assuming everything’s fine. These pumps are tough in some ways, but running dry is their weak spot. Cost me a bit of panic, but luckily not a new pump this time. Won’t be making that mistake again.