Alright, let me walk you through my little adventure with acid resistant pumps. It wasn’t something I thought I’d ever need to get deep into, but hey, projects take you weird places.

So, I had this task, needed to move some pretty harsh stuff. We’re talking acidic solution, not water, not oil. My first thought, probably like a lot of folks, was that maybe one of those tougher-looking sump pumps or something similar I had lying around could handle it. You know, give it a good rinse afterwards? Yeah, that was naive.

Finding the Right Gear

I started looking around, reading up a bit. Quickly figured out that regular pumps, especially the metal ones, were a definite no-go. The acid would just eat right through them. Imagine that mess. So, the hunt began for something specifically called ‘acid resistant’.

Found out there are different kinds. Lots of them seem to be the centrifugal type – the ones that spin the liquid really fast to push it out. Simple design, apparently pretty common. But the key thing wasn’t just the design, it was what the darn thing was made of. That’s the whole secret sauce.

- Searched online, checked industrial supply places.

- Looked at materials like Polypropylene (PP) or PVDF – basically tough plastics that don’t care about acid.

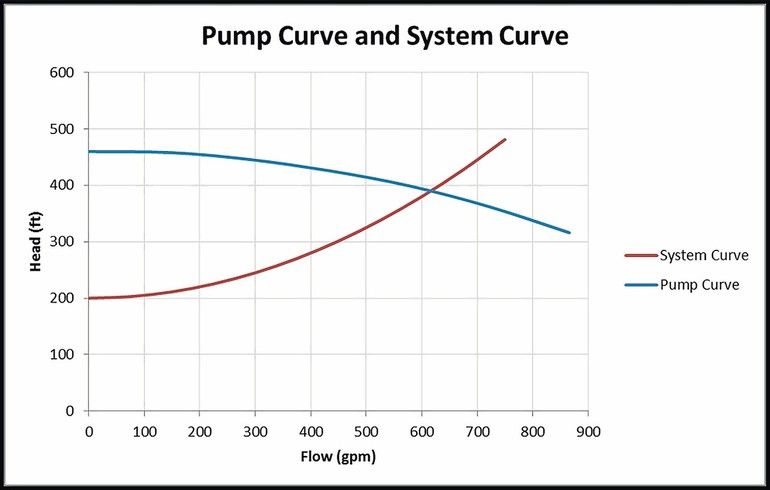

- Compared flow rates and how high they could push the liquid (the ‘head’).

Getting Hands-On

I settled on a smaller, magnetically driven pump made mostly of that PP stuff. Mag-drive seemed safer, less chance of leaks through seals, which sounded like a good idea with corrosive liquids. It wasn’t cheap, mind you, definitely more than your average hardware store pump.

When it arrived, setting it up was pretty straightforward. Hooked up the hoses – made sure those were acid-resistant too, learned my lesson there. Priming it took a minute, had to make sure liquid was in the pump head before switching it on, otherwise, it just spins air.

The Moment of Truth

Okay, time to actually run the acid. Little bit nervous, not gonna lie. Double-checked all connections. Flipped the switch. It whirred to life, quieter than I expected. And sure enough, the acid started flowing smoothly through the outlet hose into the container.

I ran it for quite a while that first day. Kept a close eye on it. No leaks, no weird noises, no signs of the pump struggling or melting or anything dramatic. Just did its job.

The Takeaway

Been using it on and off for this project since then. Still holding up fine. It really hammered home the point: for specialized jobs, especially involving nasty chemicals, you gotta get the right tool. Trying to cheap out or use the wrong thing is just asking for trouble, big trouble potentially. Spending a bit more upfront for the correct, safe equipment? Totally worth it. No question.